Details About CNC Horizontal Machining Center

The structure is rigid, the stroke is large, and the precision is high.

It is suitable for various heavy cutting and high-precision machining fields, ensuring high-efficiency and high-precision processing requirements for small and medium-sized products of single-piece goods.

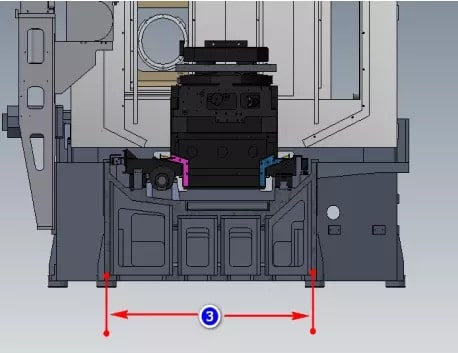

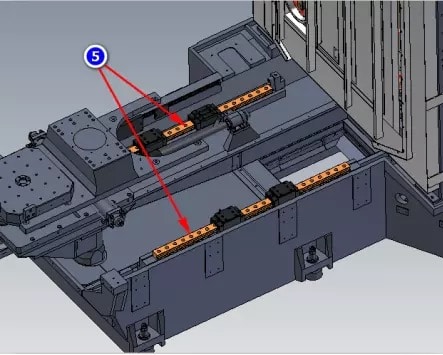

Bed Body

The structure of the machine frame is been FEM analyzed by ANSYS system to guarantee high stability under high speed and high precision machining.A deformation testing is simulated under loading simulation to ensure the rigidity and have excellent bending resistance.

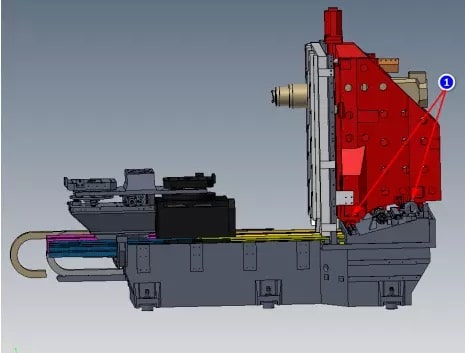

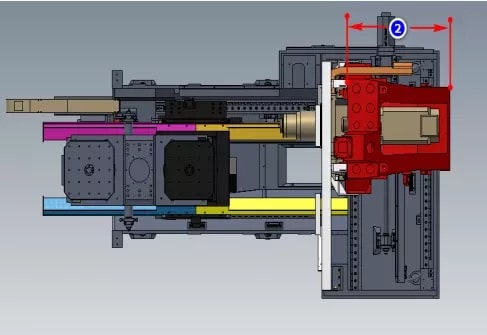

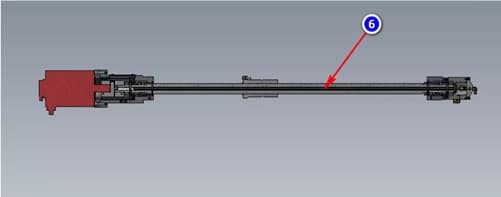

Spindle

DHM series uses the direct drive spindle. Straight type spindle motor spindle with wide area, low speed and full power output, to meet the large amount of cutting conditions and cutting.

Gear type main shaft head are integrally cast molding, has a higher rigidity than the average combined type main shaft structure, improves the stability of the machine.

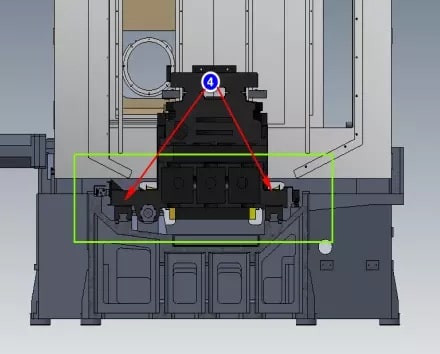

ATC(Automatic Tool Changer)

Automatic toolchanger is composed of tool magazine and tool changing arms.Automatic toolchanger is installed separately from machine tool with the purpose of preventing adverse influences of vibration during running of automatic toolchanger and other reasons on precision.

Technical Parameters:

| Model | Unit | HME63S | |

|---|---|---|---|

| Worktable | Size | mm | 630*630 |

| Max load | kg | 1200 | |

| Positioning accuracy | s | ±5 | |

| Repeat positioning accuracy | s | ±2 | |

| Machining Range | X/Y/Z Axis travel | mm | 1000/770/900 |

| Distance from spindle nose to worktable | mm | 175-1075 | |

| DIstance from spindle center to worktable | mm | 110-880 | |

| Spindle | Taper | BT50 | |

| Rotation speed | rpm | 6000 | |

| Main motor power | kw | 15/18.5 | |

| Drive | Fast feed speed (X/Y/Z) | m/Min | 24/20/24 |

| Fast feed speed (B) | r/Min | 10 | |

| ATC (Optional) | Tool capacity | pcs | 24 |

| Max tool dia. | mm | φ105 | |

| Max tool length | mm | 300 | |

| Max tool weight | kg | 15 | |

| Tool changing time | s | 3.8 | |

| Accuracy | Positioning accuracy (X/Y/Z) | mm | 0.01 |

| Repeat positioning accuracy (X/Y/Z) | mm | 0.006 | |

| Air supply | Air supply pressure | bar | 6-8 |

| Air supply flow | L/Min | 280 | |

| Others | Weight | kg | 13000 |

| Dimension (L*W*H) | mm | 4720*3430*3350 | |

As our company continuously developing and improving our products, the specification parameters might change without any notice.

Share CNC Horizontal Machining Center With Others

Share on facebook

Facebook

Share on linkedin

LinkedIn

Share on twitter

Twitter

Share on email

Email

Related products

-

CNC Horizontal Mill High Precision

$50 Add to cart -

Horizontal CNC Milling Machine

$50 Add to cart -

Horizontal CNC Machine Center

$50 Add to cart -

Horizontal CNC Machining Center With FANUC Controller

$50 Add to cart