The machining center is developed from the basic CNC milling machine. It combines all the features and functions of the CNC milling machine. The only difference from the CNC milling machine is that the machining center has an automatic tool changer, which can realize the automatic tool change function during machining. The CNC milling machine does not have an automatic tool changer, and the automatic tool change function cannot be realized. This is the only difference between the CNC milling machine and the machining center. Today, we will introduce the automatic tool changer.

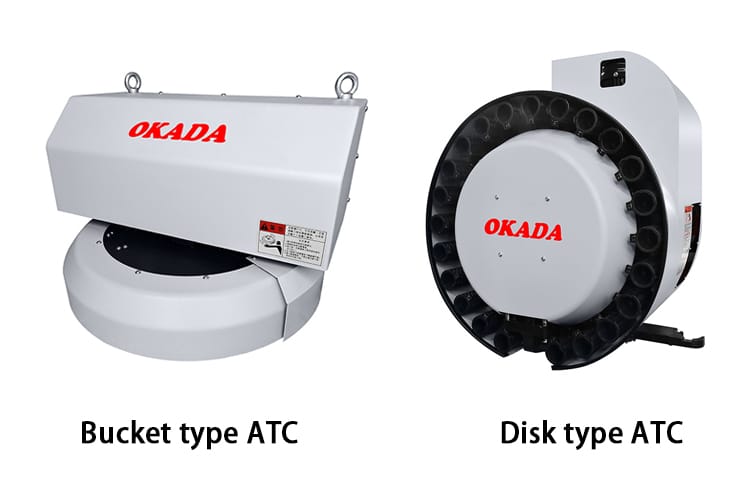

The automatic tool changer of the machining center is composed of a tool magazine, a robot arm and a drive mechanism. The tool magazine stores the tools required for machining. There are many types of magazines, mainly according to the shape of a variety of types of magazines, such as bucket magazines, disc magazines and chain magazines. These magazines have several to hundreds of tools. There are two types of tool magazines used in the common machining centers on the market: the bucket type magazine and the disc type magazine. The chain type magazine is not used by many manufacturers because of its high price. The following small series will introduce the way of changing the tool.

Tool change method of bucket magazine

The tool change method of the bucket magazine is relatively simple. This type of magazine does not have a robot arm, so there is no need to use a robot arm to complete the tool change. The tool change method of the tool magazine is as follows: the tool magazine moves to the main shaft to realize the tool change. This type has the advantages of high cost performance, convenient maintenance, simple structure, etc., but the disadvantage is that the tool change speed is slow.

Tool change method of disc type

The tool change mode of the disc type magazine is more complicated, mainly because the robot arm completes the tool change action, and the robot removes the tool from the tool magazine and rotates it into the spindle to complete the tool change. Such a tool magazine has the advantages of a fast tool change speed, and has the disadvantages of complicated structure, inconvenient maintenance, and high failure rate.