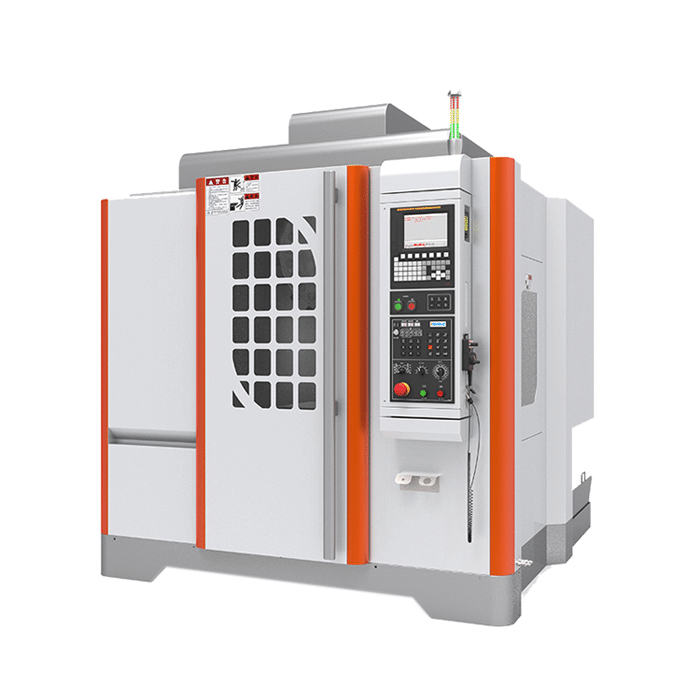

Details About CNC Drilling and Tapping Center

Features:

- Compact structure.

- Max rigidity, high reliability and high power rating.

- Direct-coupled high speed spindle with rapid reaction and high efficiency.

- High speed mute screws, hot linear rolling guides, with little deflexion and high precision.

- Three axis with high speed displacement 48-60m/Min, can save 50% of no machining time.

- Safety specification with European standard.

- High-level CNC control system.

- Incomparable cost performance.

Technical Parameters:

Model Unit T640 X/Y/Z Travel mm 600/400/300 Worktable size mm 700 (800)*420 T slot mm 3-14T*125 Distance from spindle nose to table mm 150-450 Spindle rotating speed rpm 20000 (12000) Spindle motor KW 3.7/5.5 (5.5/7.5) Triaxial motor KW 1.5/1.5/3.0 G01 feed rate m/Min 12 G00 rapid traverse speed m/Min 60/60/48 Positioning accuracy mm ±0.005/300 Repeat positioning accuracy mm ±0.003/300 ATC tool capacity pcs 21 Spindle taper BT30 Dimension (L*W*H) mm 2100*2350*2300 Weight kg 4000

As our company continuously developing and improving our products, the specification parameters might change without any notice.

Share CNC Drilling and Tapping Center With Others

Share on facebook

Facebook

Share on linkedin

LinkedIn

Share on twitter

Twitter

Share on email

Email

Related products

-

Drilling and Tapping Machine CNC Center

$50 Add to cart -

CNC Tapping Machine Drilling Center

$50 Add to cart -

Tapping Machine Center T6

$50 Add to cart